Bioenergy

The Piscataway Bioenergy facility will turn Poop to Power by transforming how WSSC Water handles biosolids. Construction on the $271M facility began in spring 2019 and was completed in spring 2025 on time and on budget.

The Piscataway Bioenergy facility will turn Poop to Power by transforming how WSSC Water handles biosolids. Construction on the $271M facility began in spring 2019 and was completed in spring 2025 on time and on budget.

Piscataway Bioenergy Facility - Where POOP is turned into POWER!

The nutrient-rich organic material resulting from wastewater treatment. Biosolids from two of WSSC Water’s water resource recovery facilities (WRRFs) are being delivered and treated at the Piscataway Bioenergy Facility, with deliveries from the other four WRRFs coming soon.

Biosolids go through a state-of-the-art digestion process generating methane gas, which is captured and upgraded on site to Renewable Natural Gas (RNG).

The amount of biosolids left over from the new treatment process will be significantly reduced and cleaner (Class A). In the future, they can be marketed as a soil amendment for gardens, lawns and farms.

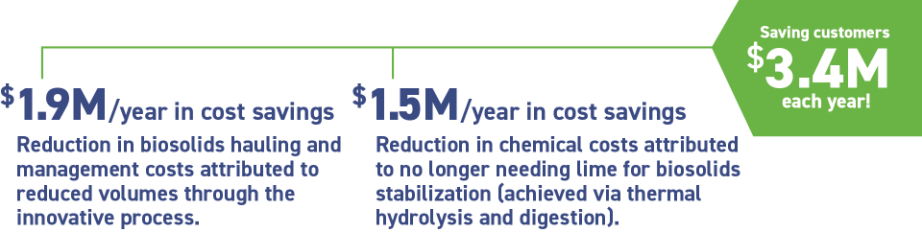

Contract with Montgomery County to sell the RNG from this facility to power their Ride On buses. Anticipate generating $700,000/yr from the sale of RNG and approximately $3.2 million/yr from the sale of renewable fuel credits.

Now supporting 20 new full-time jobs.

By recovering CO2 from the upgraded methane gas and exhaust gas from the on-site generators.

2023 Project Update Photos 2022 Project Update Photos 2021 Project Update Photos